We collaborate with the main luxury brands, sharing their ideas and dreams to transform them into metal accessories that are sure to be successful.

…from the idea to the realization

With the aim of making each project better, we make our technology and know-how available to customers.

We design and manufacture internally the molds for zamak die casting, brass die casting and brass cold cutting.

We study and optimize cam programs for the production of pre-series and productions in brass and aluminum CNC with the aim of obtaining the highest quality level.

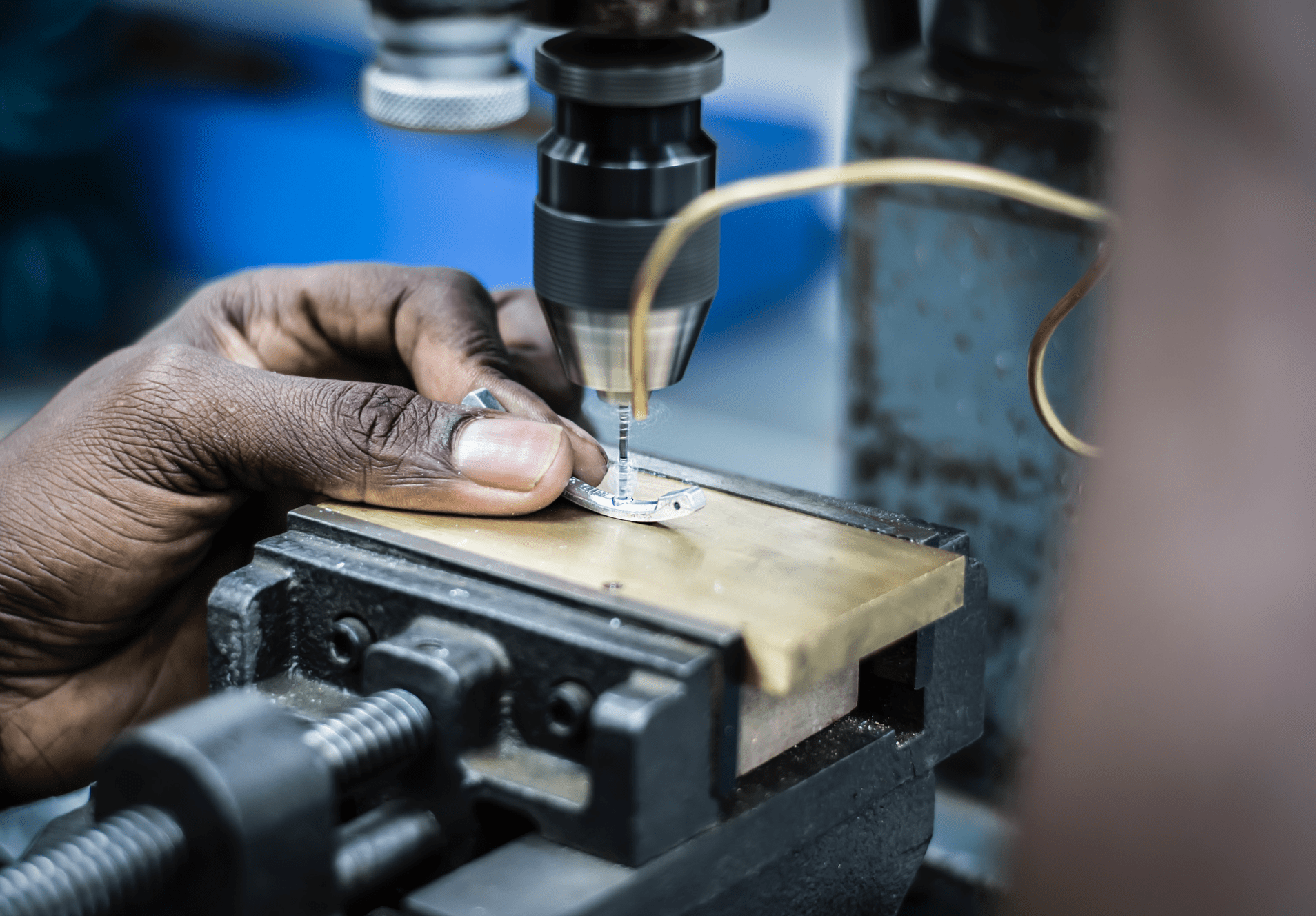

Cad and Cam design 2° 3D

Our team specialized in Cad and Cam design in 2 ° 3D, with latest generation cnc machinery, also re- alizes very complex projects starting from a simple idea. All developments are designed with a view to future industrialization. The presentation of new accessories takes place with the aid of technical drawing, rendering, three-dimensional resin prints or directly with the first brass prototype.

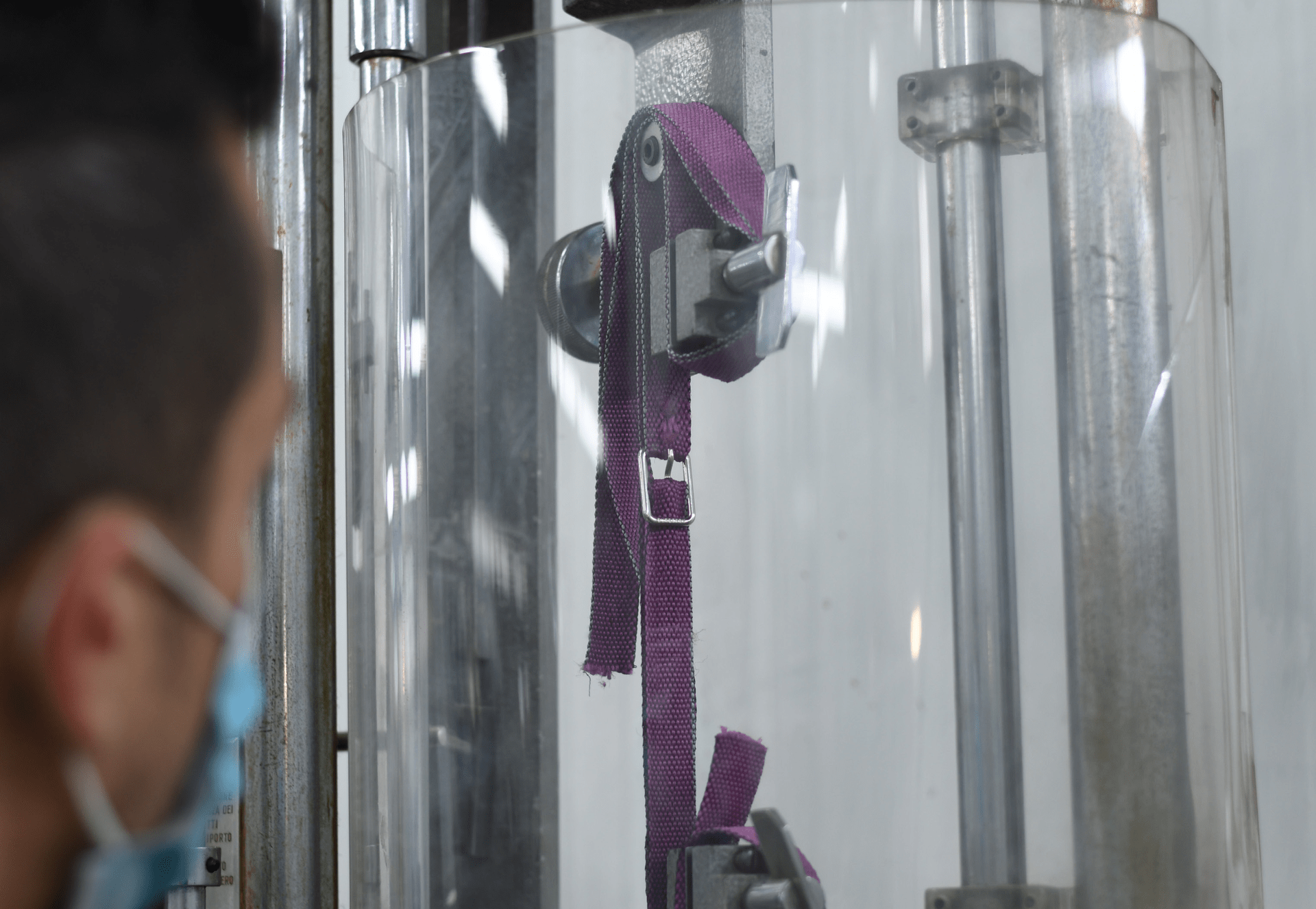

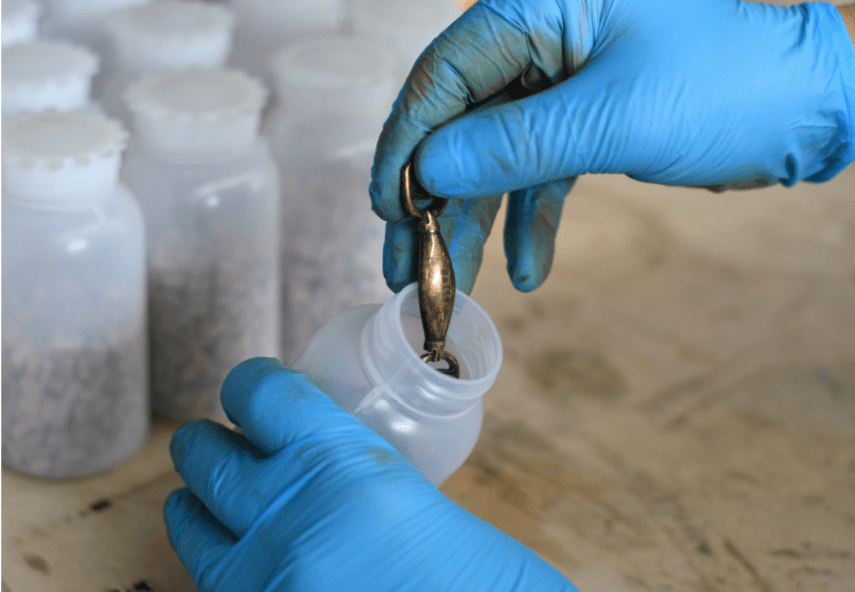

Tests and inspections

Before activating a new production cycle, we test the mold by making a pre-series to verify the quality and technical aspect of the accessory through a procedure that includes visual checks and mechanical and chemical tests.

Basic processing

Zamak die casting

The zamak die casting department consists of 6 molding machines from 40 to 120 tons, equipped with internal cameras for control and with the industry 4.0 management interface.

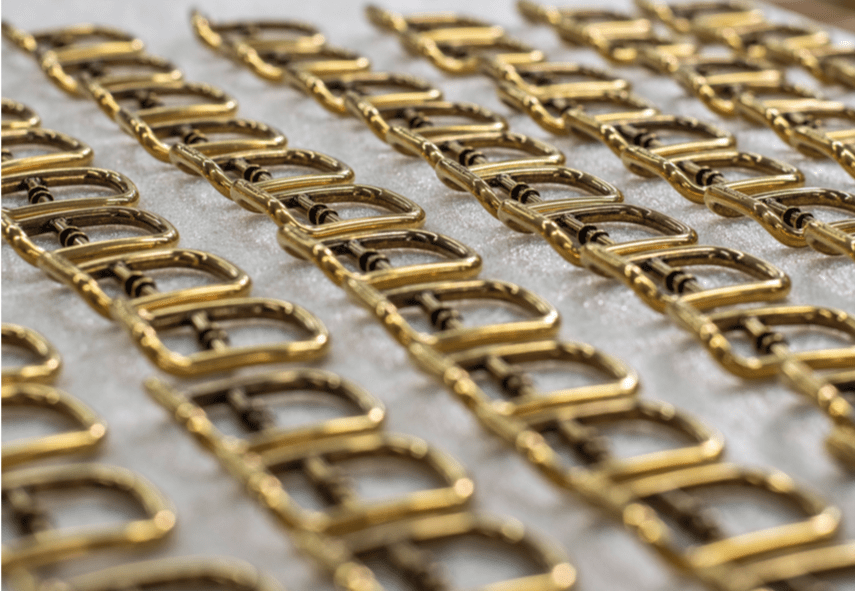

Basic processing

Brass die casting

We always look to the future and this often leads us to be pioneers of new technologies. With this in mind, the brass die casting department was recently created.

The experience gained in 50 years of work on molding techniques and mold design has allowed us to overcome the constraints of this technology applied to luxury accessories.

The brass die-casting allows to speed up the production cycle by reducing the molding times and eliminating the subsequent CNC recovery processes necessary with hot forging, still obtaining a product with very high level technical and qualitative characteristics.

Basic processing

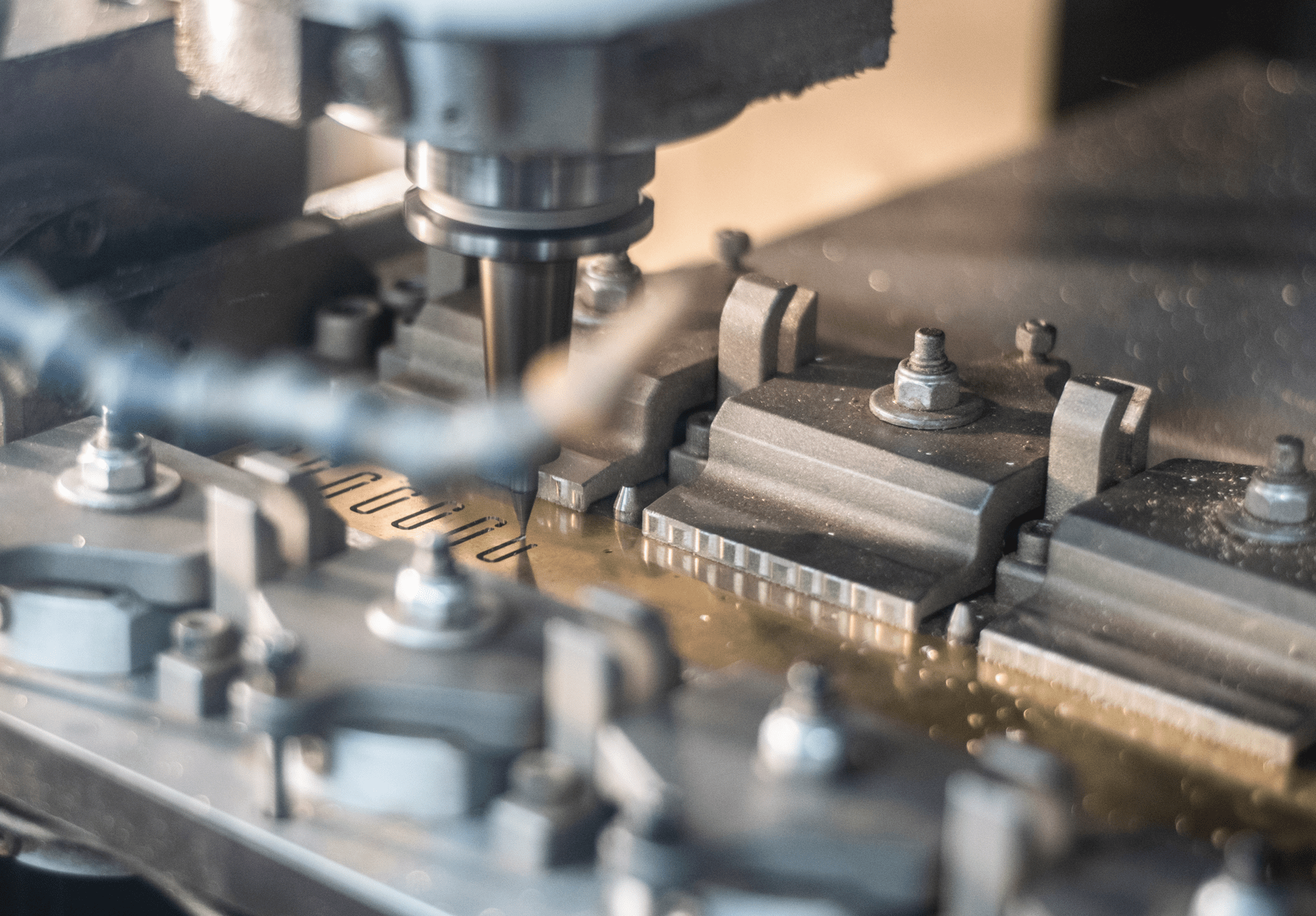

Milling c.n.c.

The department is made up of 6 cnc machines equipped with automatic loader and tipper both for the production of lead-free brass and aluminum and for the milling of the molds.

CNC milling performed on lead-free brass by combining mill and chisel processes.

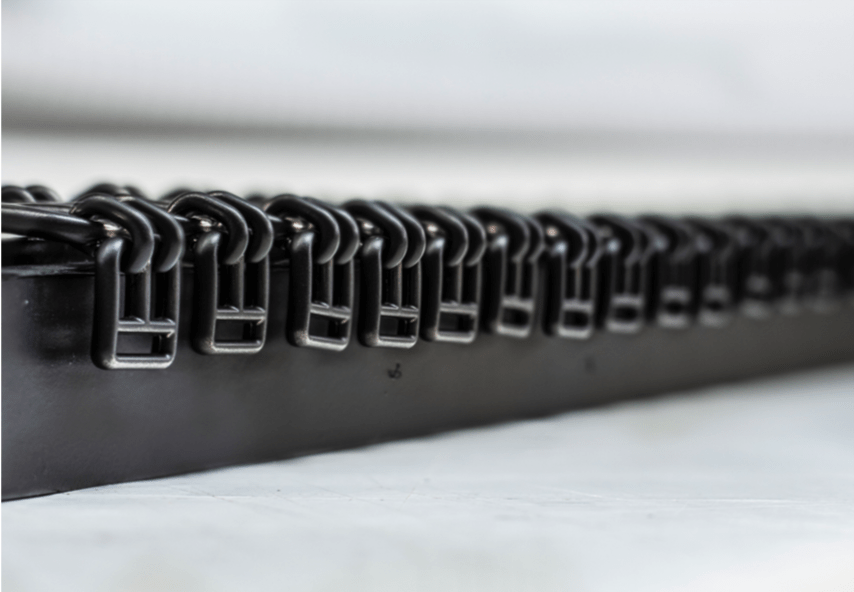

Basic processes

Cold forged brass and wire bending brass

Eccentric presses for brass molding and wire bending machines allow us to independently create customized barbels and assembly components.

Intermediate processes

Vibration

We continue to vibrate with the classic method which, according to our experience, still offers the best quality today.

The department is also equipped with an oven and centrifuge for post-vibration drying and “barrels” for the vibratory polishing of zamak and brass.

Intermediate processing

Bench processing

The department equipped with various bench machines allows to manage internally the bending, punching, drilling, assembly and welding for prototyping, sample repetitions and productions.

Intermediate processes

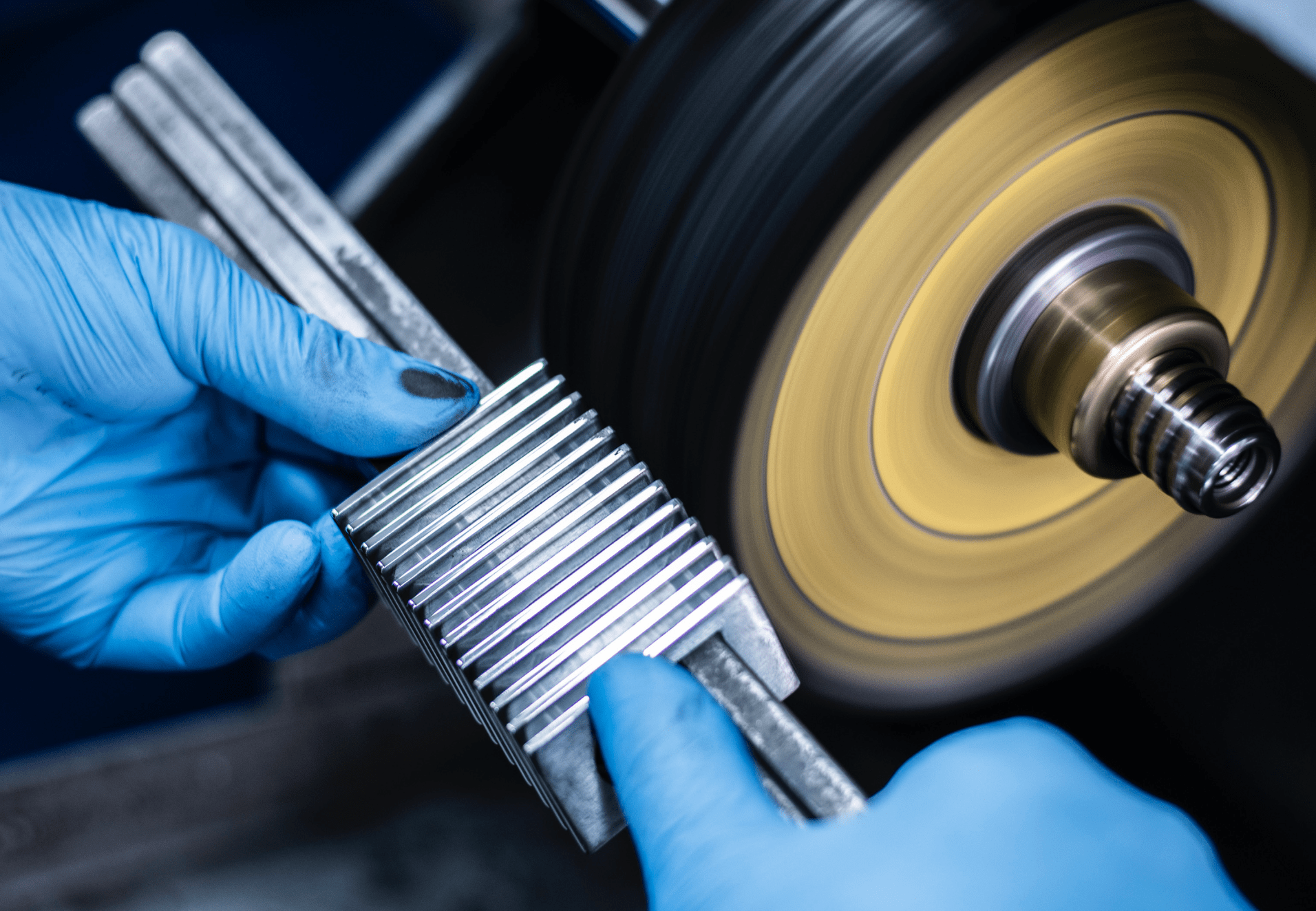

Cleaning

A small polishing department is equipped with machinery for mechanical flat and manual grinding, mechanical carousel and manual polishing and manual polishing and satin finishing. The processing cycle ends with washing in the ultrasonic degreasing machine.

Finishing

Post galvanic discoveries

We internally create post galvanic discoveries and waxes with woods, walnut shells and sawdust both in barrels and in cans.

Finishing

Painting

We create glossy, semi-gloss, matte and rubberized varnishes, offering the possibility of choosing the color from our folder consisting of 2,500 shades, on Pantone reference or customized with the customer’s color sample.

The processing takes place with placing on the frame, shelf or mixed technique inside a pressurized cabin and with subsequent drying in a temperature controlled oven chamber.

On all the lots produced we carry out hardness and squaring tests. Assembly resistance tests are also performed on small metal parts with the use of customized spare parts.

The selection of the paint supplier has been studied and finalized in order to guarantee high techni- cal performance and to pass the main chemical tests required by the brands.

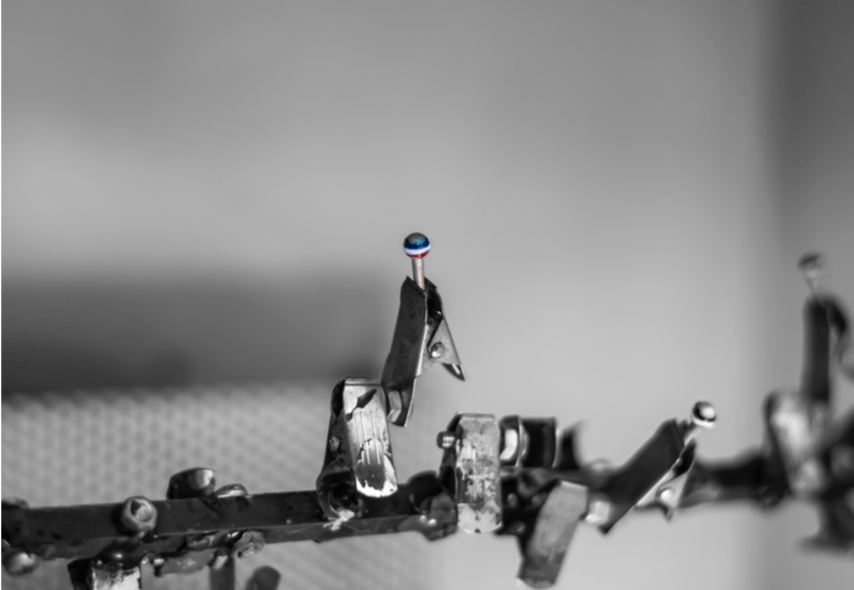

Finishing

Smooth glazing, Finished glazing, Strassing

In 2005 we opened this new department by expanding the possibilities of metal finishes.

We internally carry out enamelling on finished products, smooth enamelling on flat, curved and circular surfaces, cathedral enamelling and rhinestones.

Production

Quality control

The controls are programmed on various stages of the production process, from the raw to the finished product.

This allows to identify any anomalies in the work phases and to guarantee quality standards. Two rooms are available to customer inspectors for checking before shipment.

Packaging and Logistics

Based on the type of article and the customer’s requests, we carry out different types of packaging.

For compound articles we carry out the packaging in sets accompanied by the assembly technical sheet.

The logistics operators, in collaboration with the team of commercial production executives, send the requested documentation to the client.